Strengthen circular economy ecosystem to accomplish Aatmnirbhar Bharat

There is a need to recognise the environmental benefits for achieving long-term objectives

image for illustrative purpose

Economic growth, urbanisation, higher living standards, industrialisation in emerging economies and a growing population are driving the demand for materials globally. Though intended at reining in burgeoning imports from China amid an escalated border dispute between the two neighbouring nations, the Atmanirbhar Bharat initiative was aimed at promoting and supporting local products.

This is expected to hedge the country from the vagaries of supply chain disruption and price fluctuations, while at the same time, ensuring enough competitive advantage to local business and industry to become a major player in global trade.

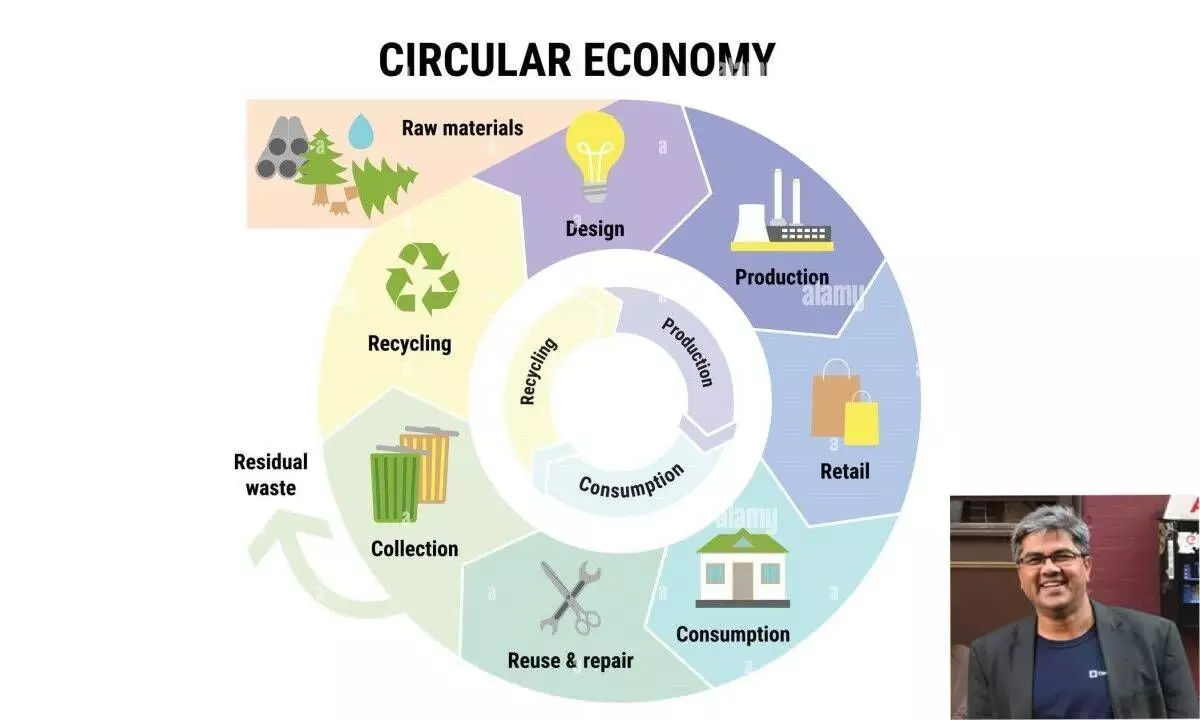

Far from the ‘take-make-consume-throw away’ practice of a linear economy, a circular economy involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials as long as possible to extend their lifecycle. The United Nations Environment Programme (UNEP) estimates that globally, the material consumption is expected to grow from 40 billion tonnes in 2010 to 90 billion tonnes in 2050.

With the growing use of materials, environmental impacts associated with materials management are projected to more than double in the coming decades. This will have adverse consequences for human health, ecosystems and the economy.

A resource-efficient and circular economy offers a number of benefits in environmental, economic and social domains. There is a need to recognise the environmental benefits for achieving long-term environmental objectives; the economic benefits with regards to competitiveness, new business opportunities, innovation, greater resilience against scarcity of resources and volatile prices; and the social benefits leading to job creation and overall growth. Thus, domestic policies need to be streamlined based on circular economy principles.

India is one of the leading importers of global waste and scrap. In 2019, the government came out with its National Resource Efficiency Policy, which is guided by the principles of reduction in primary resource consumption to ‘sustainable’ levels, creation of higher value with less material through resource efficient and circular approaches, waste minimization, material security, creation of employment opportunities and business models beneficial to the cause of environment protection and restoration, leading to advancing and transitioning the economy from linear to circular.

The development model must be based on optimum utilization of resources. It believes the key to an Atmanirbhar Bharat is to ensure sustainable growth and that the country must move towards a circular economy amid a growing population and rapid urbanization. From the point of view of climate change and its net zero targets, the transition is a must. It has been actively formulating policies and promoting projects to drive the country towards a circular economy and in this regard, it has already notified various rules, such as the Plastic Waste Management Rules, e-Waste Management Rules, Construction and Demolition Waste Management Rules, Metals Recycling Policy, among several others. Several production-linked incentive (PLI) schemes have provided the much-needed impetus towards self-reliance. However, some unfortunate developments have also come the way, providing roadblocks in the journey. One such instance is the closure of Sterlite’s copper smelter in Tamil Nadu. From a net exporter of the metal till 2017-18, the country became a net importer as soon as the plant’s operation came to a standstill following a court order in May 2018.

With record high consumption and subdued production, India’s copper import touched an all-time high in FY23 while exports reduced to a new low. Consumption touched an all-time high of 706,000 tonnes in 2022-23, gaining traction from the higher usage in multiple sectors. Production, however, is still lagging and stands at 555,000 tonnes in FY23 compared with 766,000 tonnes recorded in FY18, resulting in imports rising to an all-time high of 181,000 tonnes.

Currently, India has unexplored copper reserves and remains import dependant for supply of blister copper and copper concentrate. At present, the copper industry is over reliant on a small basket of countries for securing duty-free supply of blister copper and copper concentrate. While Zambia is the only source of duty-free blister copper import, Chile & Australia[1] are the only sources of duty-free copper concentrate supply. An abrupt disruption in the supply of blister copper and copper concentrate from either of these countries can deliver an immediate supply shock to the Indian market.

The phenomenon of tightening raw material availability is also expected to continue in the present decade. Between 2011 and 2021, the market has experienced a deficit of three million metric tonnes between mine production and refined copper demand, which is expected to rise to eight million metric tonnes by 2030 as per commodity forecaster Wood Mackenzie.

India generates copper scrap in substantial quantities. However, this scrap has not been channelled by organized sector participants. This assertion is backed by the National Non-Ferrous Scrap Recycling Framework. The framework, released by the Ministry of Mines, stated that India’s domestic scrap recycling rate of 20% is far below the global benchmark recycling rate of 82%. The framework has also recognized the need to formalize the sector by developing standards for input waste material suitable for domestic secondary processing. This development is paramount as it will prevent dumping of scrap, formerly entering China and Malaysia, into India. It will also create a system where recyclers of scrap will process scrap collected by them in a technically appropriate manner as standards will arm them with adequate data to gauge the health of scrap lot. This will reduce quality concerns with regards to copper generated using scrap as a raw material.

In the long run, it will lead to an increase in India’s domestic scrap recycling rate and create a circular economy in the copper industry. In this backdrop, India can provide a fillip to the circular economy in the copper industry by enacting policies that encourage responsible usage of domestic scrap. The cascading effect of a circular economy for copper on industries both large and MSMEs would reflect in tangible resource management and would have great economic consequence.

(The writer is with MCRHRDI of the Government of Telangana)